Manufacturing process :

Surface treatment

Plc Controlled 11 Tank Phosphating Unit

Shot Blasting M/C

Bonding Agent Spray Spm

Tool Manufacturing

Moulding plant

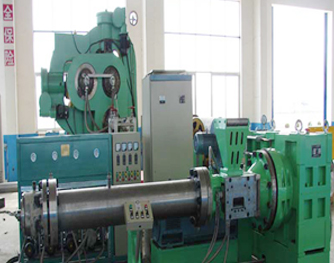

Hose Plant

With our continuous improvements philosophy, our production systems & techniques have been reformed over the years resulting in highly stable processes with efficient productivity.

Moulding : The plant is equipped with advanced and fully automatic lines of Injection moulding machines, Vacuum compression cum transfer Moulding machines and other supporting facilities.

For Rubber to metal bonded parts, we have shot blasting, aluminium oxide basting for plastics , phosphate & automatic bonding agent application machines.

We have developed highly durable products in TPE & TPU products.

Hose plant is equipped with Extrusion line with cold feed extruders , Knitting & braiding machines, Vulcanizes , automatic tube cutting machines , Fuel Tube line is equipped with co-extruders for producing multi layer tubes with different raw materials. Cross Head extruders provided to manufacture multi layer hoses with Rubber and Fabric for various applications like Radiator , Heater , Gas , Fuel lines etc.